Twelfth century China is where it began. To be more specific that's where they started using coatings to preserve food. In their case it was citrus fruit, but the basic principle is used worldwide by today's food and bakery industries.

Twelfth century China is where it began. To be more specific that's where they started using coatings to preserve food. In their case it was citrus fruit, but the basic principle is used worldwide by today's food and bakery industries.

The coating possibilities available to us today are very much greater and, as you would expect, the complexities have grown even faster! Let me try to explain how it all works as the rewards are potentially huge – increasing shelf life, improving quality, appearance and texture for the chocolate, confectionery, bakery and ice cream industries.

The way to reduce the problems like staleness, off-flavours, odours and blooming etc, is to control the supply of water, oxygen, ethanol, and, to a lesser extent a few other vapours and liquids. There are three ways to do this and all of them depend on limiting the ability of liquids and vapours to move from one area to another – the opportunities are the packaging, coatings and the use of (edible) films within the product.

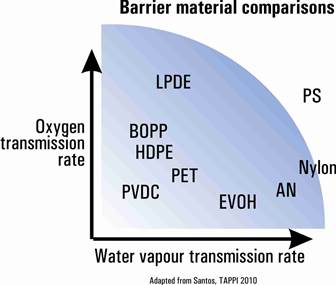

We need to control the permeability of one or more of these three barriers, and here we get to the first problem. A barrier that is great for oxygen may be next to useless in controlling water vapour – indeed most cellulose barriers fall into this category. To make matters rather worse, it turns out that different products have very different requirements.

Figure 1

Each and every confectionary and baking different product has a specific, and usually different, requirement for water vapour and oxygen films, coatings and packaging.

I am tempted to add that different aspects of a baked product, for example flavour loss, texture and appearance usually have competing requirements and the best overall results demands a compromise. However, the results can be very worthwhile – one food product we heard of managed to increase its shelf life by 800% !

Packaging

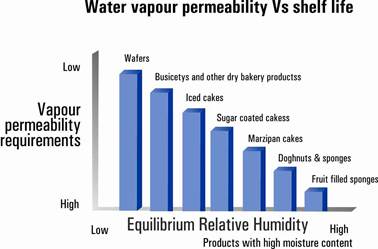

Figure 2

The most important performance characteristic for use in confectionary packaging are summarised in the first table below, the second table give examples of the permeability measurements of some of the films.

As we saw (Figure 2 above) the role of packaging varies widely – some products such as biscuits and wafers usually just need moisture to be kept out, whereas fruit filled sponges etc. need moisture kept in, fortunately the same barriers can work in either case. Many bread-like products need something very different – in particular, although moisture needs to be excluded, oxygen needs free access and there are barriers that can achieve both of these.

Material type |

Packaged product and comment |

Traditionally used packaging films eg LDPE (low density polyethylene), PVC (polyvinyl chloride), |

These films are not permeable enough for highly respiring products like fresh-cut produce. |

Tailored Oxygen Transmission Rate (OTR) |

Films for low, medium and high respiration rate commodities are now widely available. These are commonly used for artichoke hearts, baby salad greens, sliced strawberries, stir fry mixes and many others. |

High Oxygen Transmission Rate |

Broccoli, asparagus and mushrooms present a challenge to packagers. Very high OTR films (> 1000 cc/100in2-day) must be used. |

Metallocene Technology |

This technology produces flexible plastic films with very high OTR and a low moisture vapour transmission rate. |

Microperforated / Microporous Films |

These are films with holes or pores and can be used for fresh-cut fruit that is packaged in rigid, gas impermeable trays with a limited area permeable film. They can also be used for other produce with a limited package surface area. |

Figure 3

Plastic |

Parmachor values |

Permeability (ml/m2.24h.atm - 20μ film) |

Real values |

||

N2 |

O2 |

CO2 |

|||

PVA |

160 |

0.02 |

0.06 |

0.21 |

0.2 |

PVCD |

97 |

0.6 |

3.6 |

12 |

2 |

PET |

68 |

21 |

80 |

310 |

40 |

PVC |

61 |

100 |

200 |

1000 |

300 |

HDPE |

39 |

800 |

2000 |

12000 |

2500 |

PP |

31 |

1600 |

5400 |

20000 |

3000 |

PS |

27 |

2400 |

8000 |

26000 |

/ |

LDPE |

26 |

3200 |

10000 |

36000 |

10000 |

Figure 4

Edible Product Coatings, mainly external

Edible coatings have a different set of requirements to packaging. Not only do they need to control the flow of oxygen, moisture etc, but they can play a big role in appearance, texture (especially in the cases of icing or chocolate), and flavour. Sometimes they even need to hold a product together. The earliest example food-based I know of this dates back many millennia – a blood sausage was mentioned 2,500 years ago in Homer's Odyssey.

A more modern and much smarter coating example is the chocolate coating inside some ice-cream cones, not only does it tastes wonderful but it may well have been designed explicitly to stop the cone from disintegrating due to moisture in the ice-cream!

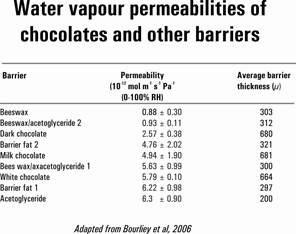

A table of the permeability of several commercially available edible barriers, compared to chocolate, is below.

Figure 5

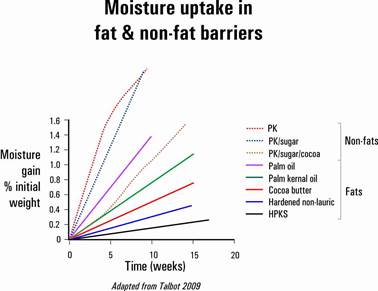

The exact physical processes of moisture migration within a product are poorly understood, though research is being carried out in this area. However, it may relate to the amount of liquid oil present in the product and can be delayed by either reducing the liquid fat content or immobilizing the liquid phase. As an example, with chocolate-flavoured coatings made from just oil and cocoa powder, moisture moves primarily through the particles of cocoa powder. If the coating contains sugar it moves along the surface of the sugar particles, but when lecithin is added it migrates both through the cocoa powder particle and along their surfaces.

Edible films, mainly internal

There are three main types of edible films:-

Polysaccharide coatings have high permeability values (poor barriers) to moisture and intermediate regarding gas (mainly oxygen) exchange. These are usually made from combinations of cellulose derivatives, starch products, chitosan, pectin, carrageenans, alginates and gums.

Proteins: have similar properties to Polysaccharides, (both are hydrophilic). They can be made from cornzein, wheat gluten, peanut, soy, collagen, gelatin, egg, whey and casein.

Lipids: together with waxes these tend be better moisture barriers than the others but more permeable to gases like oxygen and carbon dioxide. They include beeswax, petroleum waxes, vegetable oils etc.

Often barriers such as these are combined in various ways, for example a protein-lipid barrier adds the improved (e.g. lower) permeability the moisture resistance of the lipid to the mechanical strength and flexibility of the protein films. It also helps with oxygen permeability.

With all of this complexity the best results will often be gained through specialist combinations of films and barriers for the packaging, coating and edible internal films. Combining this with the issues of various coating and application methods (usually fluidized bed coatings for bakery products, and foaming, dipping, panning, spraying or electrostatic coatings for many other products) means the only practical way to determine what is best for your product is by testing it.

Figure 6Over the past couple of decades the most effective way of doing this is with a permeability meter, such as the ones we design, manufacture and use at Versaperm. With them you can obtain a accurate and reproducible results for all three types of barrier for water, oxygen (or virtually every other vapour).

Normally to test a barrier, a sample needs to be fixed between two halves of a stainless steel chamber and housed in an accurate thermostatically controlled oven. Barriers with sufficient mechanical strength are tested by themselves but most edible films are supported or sprayed onto a known substrate which does not interfere with the test. In the lower half of the chamber, the desired humidity or vapour saturation conditions are generated and a dry inert gas is passed through the upper half, where an extremely accurate measurement is made. Equilibrium is usually reached within a few hours, although in some cases results are obtained in as little as 30 minutes. This compares to days, weeks or even months for gravimetric measurements of the same materials. If you are testing a finished product, either packaged or unpacked, you can use a similar process, and the same equipment, simply replacing the upper chamber simply with the product.

As is always the case there is a lot more science and practical innovation behind this, with scholarly papers on everything from the permeability of baked crusts and their relation to the permeability of crumbs – (which turn out to be unexpectedly important) through to detailed models on mathematical models for chocolate filled confectionary and bakery products.

But however complicated the science becomes, the underlying results are clear - longer shelf life, tastier results, smarter packaging and better products. Fortunately, a lot of the practical and engineering problems of how to apply these barriers and improve your products have been solved and much of the complex science behind the barriers themselves is now understood, at least generally, if not in detail.